ProCharger supercharger systems are absolutely the most powerful

and reliable supercharger systems available for your vehicle.

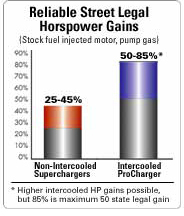

For street use or at the track, Intercooled ProCharger supercharger systems

will deliver the largest increase in horsepower and

torque available from any supercharger system.

And thanks to the extremely low charge air temperatures provided

by ProCharger technology, ProCharger systems also provide much

better engine longevity by protecting your motor from detonation.

ProCharger systems are designed with a fundamental understanding

of the physics behind supercharging, and are engineered to the

highest quality standards.

It

is this approach that allows ATI to offer exclusive features

which improve both the performance and reliability of ProCharger

systems relative to other products. For example, it is simply

an undisputed fact that lowering charge air temperatures will

substantially improve both performance and engine longevity,

and ATI provides the coolest intake charge air temperatures

in the industry by a wide margin. Similarly, by using CNC machining

and nearly indestructable 7075 T-6 aircraft aluminum to

produce the largest and strongest impellers in the industry, ATI

is able to again improve both performance and reliability.

ProChargers are the only superchargers to incorporate billet

impellers in production models, and this is another example of

ATI's technical leadership. This quality and durability in turn

allows customers to have further peace of mind knowing that

ProCharger superchargers are also backed by the best warranty in

the industry, for the highest boost and power levels. It

is this approach that allows ATI to offer exclusive features

which improve both the performance and reliability of ProCharger

systems relative to other products. For example, it is simply

an undisputed fact that lowering charge air temperatures will

substantially improve both performance and engine longevity,

and ATI provides the coolest intake charge air temperatures

in the industry by a wide margin. Similarly, by using CNC machining

and nearly indestructable 7075 T-6 aircraft aluminum to

produce the largest and strongest impellers in the industry, ATI

is able to again improve both performance and reliability.

ProChargers are the only superchargers to incorporate billet

impellers in production models, and this is another example of

ATI's technical leadership. This quality and durability in turn

allows customers to have further peace of mind knowing that

ProCharger superchargers are also backed by the best warranty in

the industry, for the highest boost and power levels.

In addition to absolutely unmatched performance

and reliability, ProCharger supercharger systems also offer

the following benefits to customers:

Quality

ProCharger supercharger systems are produced from the finest

materials available. All castings are poured from "virgin"

356 aluminum alloy and heat-treated to a T-6 hardness before

CNC machining. ATI's exclusive billet impellers are machined

from 7075 T-6 aircraft aluminum, while the super precision bearings

used in all ProCharger models are made in the USA, and are of

a consistently higher quality and speed/load rating than those

used by any of our competitors. In fact, ProCharger superchargers

are so reliable that they are used as standard equipment by

many leading boat manufacturers in the extremely demanding marine

environment.

Complete Systems

Fuel-injected automotive and truck ProCharger Systems are generally

100% complete, with all the components needed for an attractive,

OEM-quality installation. An exception is larger fuel injectors,

as some systems exclude these, especially if larger fuel injectors

are only needed for upgraded boost and power levels. All hardware is of the highest quality, and fuel-injected

systems include a high-flow external fuel pump as standard equipment

if necessary for proper fuel delivery. Carbureted systems are

complete with the exception of the carburetor and fuel system,

which depend upon an individual's specific motor and performance

needs.

Warranty

ProCharger superchargers are absolutely the most reliable (have

the lowest failure rate) in the industry, and are backed by

the industry's best warranty coverage. It is not uncommon to

find ProCharger systems warrantied for 1 year at power levels

which their competitors will not even warranty for 1 day.

Installation

Most Intercooled ProCharger systems can be installed in 8-10

hours with simple hand tools. Carbureted systems can generally

be installed in 4-6 hours. All ProCharger systems contain extremely

thorough installation instructions with plenty of photos, illustrations

and diagrams to help ensure a successful installation. ProCharger

systems are also supported by the industry's largest and most

knowledgable network of dealers.

Emissions

Unless otherwise noted, ProCharger systems for fuel-injected

applications meet both EPA and CARB emmissions requirements

and are classified as 50 state legal.

|

|

|